Water supply and installation pump

Water supply and installation pumps are one of the most widely used pumps for domestic and industrial use. Contact sales experts for advice on purchasing water pumps and installations. Kalasanati are sold in various types of water pumps and installations.

Frequently Asked Questions

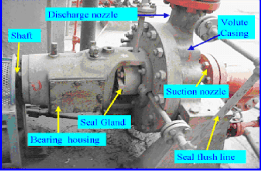

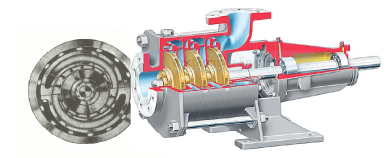

What is the appearance of a centrifugal pump?

A: In the face of a centrifugal pump, what is seen is the axis on which the propeller is mounted and fully housed inside the body of a snail shell.

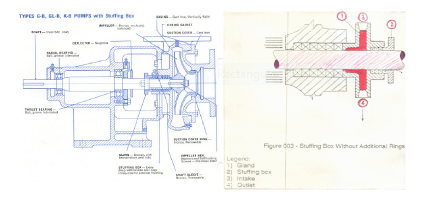

Diagram of a centrifugal pump

How does a centrifugal pump work?

A: As shown in the figure below, it will start from the points around the tab to remove fluid entering the pump impeller. At the same time as starting this work at a point 90 degrees in front of the passing fluid the same amount is here14

![]()

The liquid is pumped out of the impeller. At a 90 degree angle to the volume of fluid that is pumped out 14

![]()

The other is added in total 12

![]()

Extracts fluid from the liquid. These apply to a point called point d where34

![]()

Out of the volume of liquid, it happens. At a point called point e , the entire volume of liquid is ejected from the pump impeller.

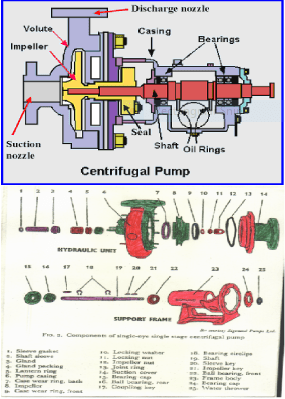

The interior of a centrifugal pump

In the event of fluid flow or fluid circulating between the impeller and the pump body, it always increases and becomes larger, causing the fluid to move in a spiral-shaped pump body when the flow occurs to the body. The cochlea pump is called. As a result of the fluid movement within the pump and the centrifugal force, the fluid eventually drives out of the pump impeller and at the same time a new fluid under the same centrifugal force is introduced as a replacement for the previous fluid. During this operation, a constant flow of fluid is placed in the inlet pipe, which is open and below the liquid surface. In this case, if the inlet pipe is above the liquid level, the liquid will be disrupted and the way for air or gas to enter the pump will open.

How does a liquid centrifugal pump get into the pump and what does it do?

A: In centrifugal pumps, the fluid enters the pump through the impeller center or the propeller eye. In most pumps, the impeller in the pump has a processing speed of 1200-3500 rpm because the electric motors drive most pumps during processing. However, it is possible that in some cabs, such as a water injection system, , Is driven by the gas turbine current and the pump speed is 5000-6000 rpm . As the fluid passes through the pump impeller, it speeds up and reaches its maximum at the edge of the centrifugal pump impeller.

What is the fluid velocity at single-stage and multi-stage pumps?

A: In single-stage pumps, the fluid will exit the impeller and then enter the output coil and increase its speed, but in multi-stage pumps, the fluid fluid velocity decreases in a channel and radial flow corridor. In the name of diffuser or diffuser, it occurs.

What is the effect of reducing and increasing the fluid velocity at the pump?

Answer: Generally, when the fluid passes through the pump, its flow rate decreases or increases, which increases and decreases the maximum pressure within the pump. A similar example occurs when a bullet fired from a gun is fired at the target.

Convert speed to pressure in centrifugal pumps in different ways

How is the pressure produced in the pump impeller?

Answer: As an example, we can say that when a bullet hits a target, its velocity increases and consequently its pressure decreases (conversion of kinetic energy to potential energy). From this example we find that the amount of kinetic energy converted to potential energy depends on the diameter and velocity of the impeller. The amount of pressure produced by impellers that are larger in diameter and have a higher rotational speed is greater than those of lower diameter and lower speed impellers.

How fast is the pump impeller?

A: The speed of the impellers on the pumps is determined by the materials used in their construction as well as the method of producing the impeller. If a impeller is not capable of producing the pressure required by a pump, then two or more impellers can be mounted in series to supply the pump with the required pressure.

How many butterflies can there be in a pump?

A: Overall, on paper, there is no limit to the number of propellers used in the pump, although it is very rare to see horizontal pumps with more than 8 impellers in their body.

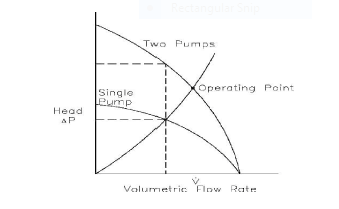

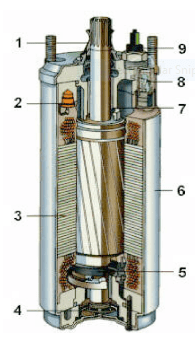

When is the second pump used?

Answer: If the amount of pressure produced by horizontal pumps is insufficient and lower than expected, the second pump will be used. The number of submersible pumps can be 50 or more. The structure of the vertical pumps is not integrated and is segmented so there is no limit to the number of impellers in the vertical pumps.

What is the difference between dynamic pumps and positive displacement pumps?

Answer: Dynamic pumps and positive displacement pumps have four fundamental differences: the

maximum amount of pressure that is limited by mechanical pumps when the fluid flow is stopped and the outlet valve is closed.

The energy in mechanical pumps is first converted rapidly and then converted to pressure by cochlea and diffuser, but in positive displacement pumps the energy in the pump is directly and indirectly converted to pressure.

Fluid fluid flow in positive displacement pumps is intermittent, but fluid flow in continuous pumps is constant.

Dynamic pumps are used for high current and medium and low pressure displacements, but positive displacement pumps are used to supply high pressure and low liquid flow, especially for viscous or high viscosity liquids.

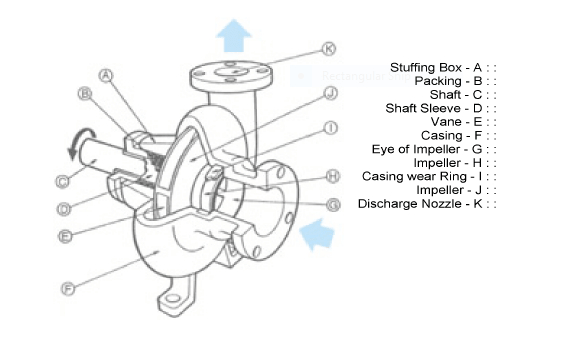

What are the main components of a centrifugal pump?

A: Centrifugal pumps have 5 main components including body, impeller, axle, bearing and sealing chambers.

The main components of a centrifugal pump

Describe the body structure of centrifugal pumps.

A: The body or shell of centrifugal pumps is the visible part of the pump that holds the other components of the pump. Common components of the body include cast iron, steel, plastic and other specialty materials. Pumps usually operated in 1000 kpa or 150 psi pressure operations in oilfield areas are usually made of cast iron, but pumps used in operation at higher pressures have a cast iron body. They are made of steel. In the pump body there are two inlet and outlet nozzles located at the bottom of the body; the upper half of the centrifugal pump body can be moved for easier inspection.

Two horizontal pieces

Two vertical pieces

What are the two axes?

Answer: It is likely that the centrifugal pump body will be in two horizontal pieces, two vertical pieces and two oblique pieces (at an angle other than 90 degrees). The term is referred to as two horizontal two-axis pieces.

How are two-piece radial pumps?

Answer: Pumps having a body with two vertical pieces are called two-piece radial pumps. These types of pumps are used in places where the drive couplings are close to and where they have designs where the inlet is mounted at the bottom on the chassis.

What is the structure of the barrel body and where are they used?

A: For pumps with high pressure and with diffusers and coils, the most likely body is the barrel body. In barrel bodies the body and inner shell are very similar to the outer barrel shell. In the barrel body, the body has two halves, which provide the leakage force required to hold the two halves together by applying the outlet pressure to the inner body.

Barrel body

What is a license and where is it applied?

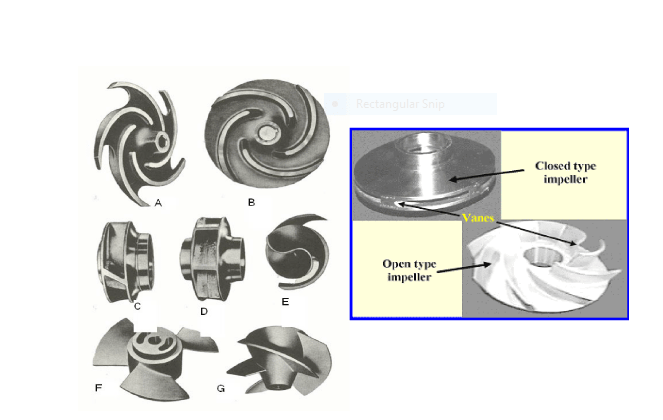

A: The impeller is a piece of a pump that works to increase pressure. The impeller mounts tightly to the pump via the pump shaft, key or press on the shaft, and does so at its rotational speed. Pumps used in oilfields have a butterfly or cast iron butterfly. Of course, corrosive and chemical services and services include plastic, stainless steel or other specialty materials.

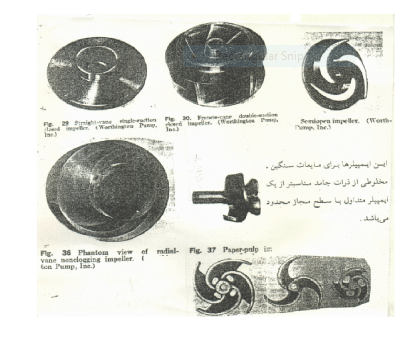

Define open butterfly, semi-open butterfly and closed butterfly.

Answer: A butterfly that has a blade attached to a central hub and is covered with a relatively small wrapper around the blade is an open butterfly. Open butterflies only have wrap and cover on one side, and closed butterflies are butterflies on either side that have wrap or walls that create pathways and channels for fluid.

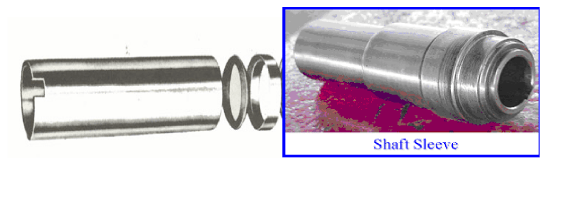

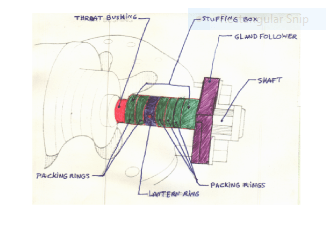

What is the pump shaft? What is its structure and sex?

Answer: The axle is part of the pump that is inside the body and its rotational speed is equal to the actuator speed. The axles are usually made of steel. In order for the shaft to withstand corrosion and abrasion, part of it is mounted in a seal, packing and sealing compartment may have bushings or sleeves made of hard metals such as tungsten and carbide. Bushes and sleeves have a duty to protect the axle against corrosion and wear and tear.

How are the bushes used in large and small pumps?

A: In large pumps, bushings of different shapes are used, but in smaller pumps, bushes are more commonly used to reduce the amount of hydraulic losses and palletization.

What is the duty of the bearing on the pump?

A: The bearing in the pump has two main functions: First, the bearing must be able to hold the pump shaft so that there is no vibration inside the body. The second task of the bearing is to prevent longitudinal and horizontal motions of the pump axle so that parts that are rotating do not hit the body.

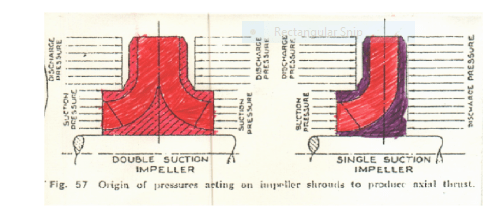

What is the reason for the bearing design and placement in the pump?

Answer: When the impeller starts to rotate at the pump, the axial forces (horizontal and thrust) are created and increased, which is the reason behind the thrust and thrust movement; Place the pump so that it can withstand horizontal forces and thrust. The bearings have a lubricating oil part of their housing that is mounted for lubrication.

Where is the bearing in the pump?

A: The pumps used in operation are small pumps that may be located on the left side of the pump body, but in large pumps the bearing is located at one end or on either side of the pump axis. .

What are the types of bearings used in pumps?

Answer: By examining centrifugal pumps, it is concluded that all types of bearings can be used in pumps. The most commonly used bearings in pumps today are anti-friction bearings, bush bearings, and Keynesian bearings. Kinsbury bearings are bearings that control the longitudinal and axial movements of the pump shaft.

Where are the types of bearings used?

A: Anti-friction bearings are made in two types of single row or double row. Barrel roller bearings are mostly used in large pumps. Bush bearings are available in either horizontal or vertical form. Kinsboro axle bearings are also used in large pumps.

Kinsbury Bearing

What is the function of sealing chambers in pumps?

Answer: If the centrifugal pressure of the pump is below the atmospheric pressure, the sealing chamber will prevent air from entering the pump, and if the internal pressure of the pump exceeds the atmospheric pressure, it will minimize the leakage of fluid out of the pump space to a minimum. Will deliver.

What is the structure of a centrifugal pump sealing chamber?

A: The sealing chamber of a centrifugal pump is solid and closed with no lantern ring. The sealing chamber is also made in two other designs with a fluid sealing tube and a lantern ring or ring.

What to do to cool the sealing chamber?

A: In a variety of pumps that perform hot fluid displacement and have a high pressure sealing chamber, the water ducts surrounding it are used to cool the sealing chamber. However, in some pumps the liquid inside the pump is mixed with the cooling fluid.

What problems do they use with the design of open sealing chambers?

A: Many services and services where the inlet pressure and temperature are high, especially where the temperature and pressure changes are higher than usual, have difficulty performing the proper adjustment of the sealing chamber. Open sealing chamber designs are used to resolve some operational problems.

What is the role of the teeth in the sealing chamber?

A: There is a bushing in the sealing chamber mounted on the pump shaft; this bush has teeth on its outer diameter and rotates about a distance from the body of the pump housing. The teeth on the main diameter of the bush break the pressure and control the leakage and then collect the leaked fluid through the pipe and remove it from the pump.

How do they keep heat away from the bush in centrifugal pumps?

Answer: In centrifugal pumps in centrifugal hot water services to keep the pressure away from the pressure cooker, cold water with higher pressure than the inlet pressureI Into the seal compartmentI Injection pumpIQomI. Cold water injectorIAh, leakI WeIPut it inside the pumpIReduces and decreases M.IThe temperature of the pump noIZ is effective and of course forI A.INot to shake the axis at intervalsIK eraI ForwardIRI Slow, of evaporationIUsINoITo preventI ViewID.