Types of industrial gearboxes

Frequently Asked Questions

Are the industrial gearboxes available in the coupled gearbox market?

A: Generally, all types of industrial gearboxes available on the market are unpaired. But there are also factories that offer their products in the form of electric gearboxes or gearboxes. For example, Sharif Isfahan Company offers a large part of its industrial gearbox coupled with Tabriz Motogen Electrogenerator or Electrogenerator.

Of the types of industrial gearboxes, what is the best coil gear available in the Iranian market?

Answer: Different brands produce cochlear gear and one of the best Iranian gearboxes in producing cochlear gear is Sahand factory of Isfahan which has produced cochlear gear in many proportions.

Which industries are most used in industrial gearboxes?

Generally, industrial gearboxes are high endurance and therefore more applicable in heavy industries. Examples include chipboard gearboxes, steel industries, cement industries, copper and zinc industries, petrochemical gearboxes, gearboxes for rolling steel, industrial gearboxes for lifts, for melting furnaces, crane gearboxes, heavy duty gearboxes, balmill gearboxes, Concrete mixer gearboxes are widely used as industries.

What is the difference between a reducer and a reducer?

A: The gearbox has the most consumption in the market and in this industrial gearbox the torque is increased in exchange for the reduction.While in incremental gearboxes, the torque will increase as the torque decreases.

What information is needed to select an industrial gearbox correctly?

Answer:

1- Rpm ratio (output split by gearbox input)

2- Input power to industrial gearbox (kWh or horsepower electromotor coupled)

3- Required output torque size (generally in Newton) Estimated

Required Output (generally expressed in rpm), of

course, the safety factor of the industrial gearbox, the type and conditions of installation of the industrial gearbox (inlet and outlet diameter), ambient temperature, type of transmission between the motors. And gearbox (direct, variator, coupling, etc.), industrial gearbox efficiency, gearbox body and other parameters to choose the best gearbox Among the types of industrial gearbox will be impressive.

Which industrial gearbox is more efficient?

A: Generally, solar (planetary) gearboxes have the highest efficiency (up to 98%) and can withstand high input speeds. Depending on the gear type, the helical gearbox has an efficiency of between 80% and 90% and the efficiency of the coil gearbox is between 45 and 55%. It should be noted, however, that the irreversible property of many coils has a great deal of market use.

What are the Benefits of a Solar Gearbox?

A: Solar gearboxes, as the latest generation of high efficiency industrial gearboxes, have gained a special place today. Among the important benefits of solar gearbox are:

1- High speed range between 0.4 to 500 rpm

2- Torque range between 650 and 500,000 Nm

3- Very low volume even up to 1.4 times the same gearbox

4- Tolerate vertical and horizontal load High on shaft

5- Very low sound

What is the Best Electro Gearbox for a Lift?

A: The lift gearbox must be irreversible and in addition to the brake motor. The coil gearbox has the property of 40 or higher ratios and the coil gearbox can be the best option for lifters.

How does gearbox construction method and quality affect its efficiency?

A: The method and quality of gearing, shaft and lubricant quality, shell joints, shell material, bearings and other considerations to make a significant impact in increasing gearbox efficiency, reducing temperature produced, reducing oscillations and also noise produced by the gearbox. has it.

Which industries does the sliding valve gearbox use?

A: These gearboxes are used in the water, oil and gas transportation industries.

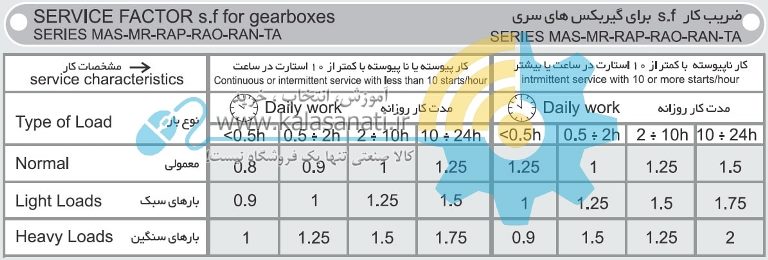

What is a Service Factor ?

A: Gearboxes generally operate under variable loads, so it is much better to select gearboxes with a suitable work factor. The following table shows the different working coefficients. In cases where overload is applied momentarily to the gearbox and is driven by a combustion engine, the following coefficients will be multiplied by 1.2.

Where's the Electro Gear Boom?

A: ISO8579-1 can be used to measure sound and detect it as normal or abnormal . This is the standard used to determine the noise level of a gear. There are three things that should be taken into account when listening to an unusual sound from the gearbox:

1- The sound can be from a gearbox, depending on whether it is gear or bearing, and so on.

2- Sound can be from the gearbox and the consumer. Gear or belt coupling and gear or gearbox coupling should be checked.

3. Improper installation or replacement of the chassis is another reason for the unusual noise in the gearbox.

How to reduce gearbox noise?

A: The noise in gearboxes can be due to a variety of reasons : 1- Inadequate oil, 2- Gear fracture, 3- Bearing failure, 4- Extra load and 5- Incompatibility with electromotor and consumer

solutions Related reasons are as follows : 1- Removing dirty oil and adding oil, 2- Gear replacement, 3- Worn bearing replacement, 4- Reduction of gearbox size or replacement, and 5- Modification of gearbox assembly.

Bevel helical ( Bevel Helical ) What does it mean?

A: If the helical gearbox is intended to be non-linear and 90 degrees angular, the Gevia gear is called Bevel Helical . These gears can be straight or spiral.

Why use industrial gearboxes ?

A: Conventional electric motors are marketed with specific torque and torque. But many industries of the era require different speeds or torques. On the other hand, some devices may require rotation angle. Gearboxes have fulfilled these needs well and have made a special place in the industry today.

What is the ratio of torque to torque in an industrial gearbox ?

A: In an industrial gearbox, torque is inversely correlated; that is, an industrial gearbox can increase torque or decrease the torque output axis by reducing torque. Ideally, an industrial gearbox has a definite definition that states that the torque output at the torque, at the input and output of the gearbox, is constant, but since there is usually energy loss in mechanical devices, the output will be lower at the output axis. .

What are the important factors in choosing an industrial gearbox ?

A: There are several factors involved in choosing an industrial gearbox, such as the

type of machine selected, ambient temperature, ambient conditions such as dustiness, humidity, frost, drive motor (type and characteristics), type Transmission between engine and gearbox (direct, via coupling, belt and polar or variator), axle arrangement and radial load value.

How many industrial gearboxes are there?

Answer: Industrial gearboxes are generally classified into seven types:

1- Cochlear gearbox - Has a wide variety and is the most used. 2- Helical gearbox - It can be divided into different types of helical gearboxes with base flange and helical flange-driven helical gearboxes. 3. Solar gearbox (or planetary gearbox) - are the most efficient and have a special place in the industry today. Compound Gearbox - Compound gearboxes are generally used in places where very little distance is required. 5- Pendant gearbox 6- Crownville pinion gearbox- Rap gearbox

How is the output torque of the electro gearbox calculated?

Answer: There are many relationships to calculate the output torque of the electro gearbox, but as a simple equation, we can use the formula? = P × 955 / n² where the letter T is the torque sign, the letter P is the power sign , and the letter n دور is the far-end sign. Calculate the output torque of the electro gearbox. The output torque can be calculated by calculating the torque and applying the safety factor from the relevant industrial gearbox charts provided by the factory to calculate the output torque.

What are the uses of industrial gearboxes?

Answer: Nowadays industrial gearbox has a special place in different factories and industries. Different applications can be imagined

for an industrial gearbox . In rail transportation for pulling passenger carriages, such as winches for dam valves, in water and oil transmission lines such as sliding valve gearboxes in Iran The Sahand Isfahan gearbox company is one of the companies that produces valve gearboxes. , in Fork (generally the gearbox casing used that are not reversible), in agriculture, especially irrigation of increasing transmission or gearbox behind tractor for accelerating Gardon on the tractor and used to pump high-speed transmission.

It also supports industrial gearboxes in single-phase and three-phase winch cranes and in three-phase winches, in traction and rolling machines, in building lifts used to clear glass in tall buildings and towers, in the municipal sewer aeration system. , All kinds of rock wagon gearboxes and other heavy loads .

Industrial gearboxes used in the manufacture of mixers and batching machines, gearboxes for rotary kilns for building materials, industrial gearboxes for rollers, gearboxes for drilling rigs, construction of billboards, use in sugar factories.

In addition, the cement industry uses a variety of industrial gearboxes in large sizes. In the chemical industry, in the defense industry, refineries, food industries, petrochemical plants, paint and enamel factories, and in the copper and steel industries, gearboxes are also widely used.