The first step in the design and selection of the electropump is the ability to calculate the longitudinal drop, local drop and loss along the pumping path. To calculate the drop in pipes and ducts there is a relationship that is mentioned in the pumps section. Household pumps for selected according to the number of floors and the size of the apartment, using the table provided in various products, as some of you chose the right pump.

Pumps are equipment used in industrial and domestic applications to move fluid from a low pressure point to a high pressure point. Pumps are generally divided into two groups or types in terms of their general characteristics: positive-displacement pumps and positive-displacement pumps.

Pump video tutorial

common questions

What is a Shaft Pump?

In the old days, shaft and screw pumps were used before centrifugal or centrifugal pumps were built. In these pumps, due to the mixing of oil in the pump equipment with the pumping fluid, which is water, it changes the quality of water and is not suitable for drinking water use.These pumps are probably still used in places where the depth is less than 100 meters. That is, they place a rubber spider every three meters instead of the sheath, preventing oil from entering the well.

Which electropumps are used for the pumping of drinking water?

A: Floating pump, water bearing pump and slurry pump are used.

Which pump is used in the boiler feed system and power plants?

A: Boilers usually have high pressure. Therefore, centrifugal pumps or class vertical pumps are generally used for these pumps. Power plants use pumps that have very sophisticated and expensive mechanisms that are capable of producing 150 to 200 atmospheres of pressure.

What pump is used to ventilate the salon? What pump is used to channel fluid into the channels?

Answer: The best pump for ventilation of the halls is the axial pump, and the best pump for channeling fluid into the ducts is the centrifugal pump or the use of an exhaust fan. A simple example is the water cooler butterfly.

What pumps are used in cooling and heating packages and installations?

A: Circulatory pumps are generally used if the facilities are small, such as home packages. In large installations, centrifugal pumps can also be used.

What is the best electropump for high-pressure water supply in power plants?

Used for low viscosity and low viscosity feed pumps (also known as power plant pumps) and plunger pumps, and for slim or viscous fluids such as concentrated oils, bitumen, etc., piston or gear pumps are used.

What kind of pump does the steel industry use?

Pumps with high drainage and discharge are most used in the steel industry. Double suction pumps are one of the most widely used pumps in the steel industry.

In which industries is the stainless steel pump menu most used?

Menu pumps, and especially the type of stainless steel, are more commonly used in the food industry.

Where is the vacuum pump used?

The polyethylene pipe industry is the most widely used vacuum pump.

What does a positive displacement pump mean?

At the positive displacement pump, fluid entering the pump is forced to drain. For example, the piston pump and gear pump are positive in the displacement pump group. In these pumps, according to the mechanism, the volume of the inlet fluid is equal to the output. All positive-displacement pumps, without exception, require a reliable valve at the pump outlet. If, for any reason, there is a blockage in the gearbox or piston thrust path, one of the following problems will definitely occur:

1- Or the engine will burn under load. 2- Or you will cut the shaft axis. 3. Or the pump body will burst. Either the transmission system will fail.

What happens at the centrifugal pump if the pressure is increased?

A: Contrary to popular belief, if the centrifugal pump or centrifuge is pressurized, the electromotor will be less loaded. In centrifugal pumps that are in the category of non-positive displacement pumps, the fluid entering the pump is not forced to exit. This means that the pumps will run smoothly for a short time if the drift path is blocked. Note, however, that this is not the case in the centrifugal pump in the axial pump. For example, if in a conventional centrifuge pump or a class pump called the VKL pump,They are told to block the thrust for a short time, the engine will be less loaded but it should be noted that due to the propeller rotating in the water and converting mechanical energy to heat, the water inside the pump can quickly warm up and may Boil. This heat and water vapor in the pump will damage it and the graphite yarn or flood of the pump will burn.

How much should the water pressure be for residential homes?

In general, the water pressure delivered to the house should be such that it reaches the second floor (6 meters). Depending on the valves used in the home, the amount of pressure varies, but on average it is best if the back of the valve is 4 to 5 meters of water column. Also in a house not all valves are always open and it should be noted that the calculations are generally calculated for two open valves and have their own calculations that appear in hydraulic books.

How to compare two pumps?

In general, the standards of each pump are in product catalogs and in manuals, and can never be compared between two pumps from two different factories. In recent years, universities have come up with a special number called the special number to compare two pumps with two different non-dimensional brands. In other words, two products from two factories can be compared when their specific number is equal. In the new catalogs, large factories have also grouped the pumps by special number. The relation from which the special number is calculated is found in various sources.

What pump do they use to deliver very thin slurry?

A: Generally, using a centrifuge pump, all liquids that have a water-like property can be pumped. It should be noted that depending on the density, viscosity and other properties of the pumping material, the pump itself must be selected.

What is the best pump order site?

In most pump plants, there are generally three categories of pumps, namely Grade 1, 2, and 3 pumps, respectively. Grade 3 pumps are mass-produced and have their own catalog and specifications, which means that all general pumps on the market are in this category. Grade 2 and Grade 3 pumps are custom made and will naturally have a higher price. Grade 2 is less sensitive and has a lower price tag. Eastern Rotary Machines Group ( KEC ) is one of the largest pump manufacturers in Iran. In addition to producing pumps, this group also repairs industrial types of pumps. To submit your pump repair order, submit your request here .

How is the diameter of the inlet and outlet of the pump determined?

A: Generally, pumps of any size can be used at the pump outlet, but at the pump inlet the size of the tube or collector must be chosen to be below 2 m / s. The higher the speed at the pump inlet, the greater the likelihood of cavitation and damage to the pump.

How much water does the 3-inch pump carry?

Answer: A 3-inch pump delivers about 8 to 10 liters per second. It should be noted that this value is empirical and the exact value depends on different parameters.

Where is the slurry pump or slurry used?

Answer: The slurry pump is most commonly used in mines used for conveying slurry. For example, in the gold and precious metals extraction industry, the ore is first converted from rock to powder (150 to 400 microns) by mixing with water to form a slurry or slurry and this slurry is pumped to the slurry and then pumped. It will be treated with cyanide and other precious metals. In Iran, of course, the most common use of pumps is in iron ore mines. The density of the slabs sometimes reaches 1500 kg / m3.

Speed transmission line and aßlar slurry Slurry is how much?

A: In a transmission line that generally operates with a suction pump, depending on the weight of the solid particles in the suction, the speed should not be less than the limit because it will cause the solid particles to settle and blockage will occur.

What parameters are measured in the pump test?

Answer: For the test of the pump in the hydraulic laboratory, generally parameters such as discharge (discharge), efficiency and absorption power are measured as the basic parameters.

What is a ram?

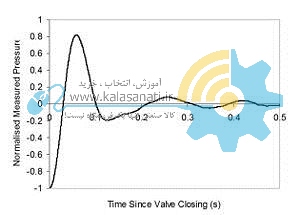

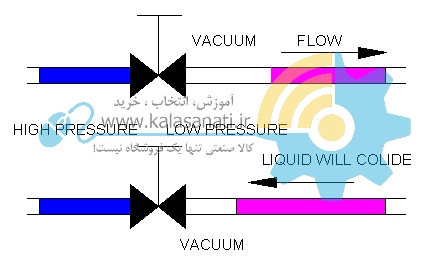

Answer: Water Hammer) In all non-compressible, non-compressible fluids that are pumped or driven, the ram will blow if we have a sudden change of speed. When the pump is operating normally, the flow rate is constant over time. But if the pump is turned off suddenly, it will stand at a fraction of a second, given the inertia of the rotating parts in the electromotor that drives the pump. But the water inside the pipe will continue to move and will return to the system due to pipe friction and gravity. The fluid will circulate in the tube for about 5 seconds, causing low and high pressure. When the pressure is too low to reach the vapor pressure of the fluid at the same temperature, the water boils and produces bubbles and cavitation will occur. Fluid separation will also hit the system along the pipe and back to the pump. To this effect, water hammer, ram blow or Water HammerCalled. The following images show the pressure changes over time and the vacuum created by the sudden blockage of the tube.

A: In large warehouses fire pumps are generally used. To choose the best anti-fire pump is required by the hydraulic calculations of Fire BoxFire Box to acquire it through the head and fire pump flow will be calculated. Depending on the head and the discharge obtained, one will usually choose one of the centrifugal pumps for this system.

How fast is the pressure wave propagating in the pipes?

A: The airspeed is about 340 meters per second, known as the Mach number. But the pressure wave propagation rate in the steel pipe is about 1400 m / s, in the asbestos tube about 1200 m / s, in the polyethylene pipe about 350 m / s and in the GRP pipe is about 500 m / s. This propagation speed is used for ram impact calculations.

What is the pipe chimney that is inserted into the pump drum?

Answer: In areas where water is not likely to freeze, pipe flue is used instead of an expansion source. The height of this exhaust is equal to the maximum of the pump head. In the south of Iran and even in Kerman, this water pipe is used. Turning off the water pump in the chimney pipe will drain the pipe and prevent the ram from impacting.

What are some ways to prevent a ram?

Answer:

1- Using expansion source

2- Using tube chimney (very limited and almost obsolete)

3- Using inverter for motor

4- Soft starter (It takes 30 to 60 seconds to start electropump) Get a quick name and it will take a while for the pump to stop - unless power cuts off)

How does cavitation occur at the pump?

A: If the pressure in the suction pumps is lowered to less than the vapor pressure of the fluid, the fluid will evaporate and the gas produced in the pump will cause a cavitation phenomenon. The sudden start of the high-speed pump and the rapid removal of the impellers will be one of the reasons for the pressure drop in the suction opening. Rapid rotation of the impellers will cause the blades of the impeller to vacuum and water in that range to steam. The bursting bubbles will corrode the pump impeller and increase the noise and vibration of the pump.

What can be done to increase efficiency in a pump that has a constant start and stop?

Answer: Using an inverter or drive will cause the least damage to the pump each time the starter and stop start causing a low start-up current. In general, the inverter can be used for unlimited startups and stops.

What is Industrial Milk?

Re: industrial valve or valves ( Valve ) is a means for switching the fluid flow in the pipeline and pipe networks and industrial environments used. Industrial valves are manufactured in different types in terms of shape and flow restriction. Volvo components and structures vary depending on the temperature and pressure range in which Volvo operates, the type of fluid (gas or liquid) and the amount of fluid corrosion. In other words, the two valves in the same classification may differ in appearance.

What are the types of valves used in different industries?

Answer: Industrial valves have different types of application depending on:

1- Gate valve

2- Lubricated plug valves

samurai valve Non Lubricated plug valves samurai valve

4- Ball valve valve

5 - Valve Check Valve

6- Butterfly Valve Butterfly Valve

7- Globe Valve

8- Needle Valve Valve

9- Diaphragm Valve

10- Excess flow valve

What to do to control Dubai during the day, where consumption is different?

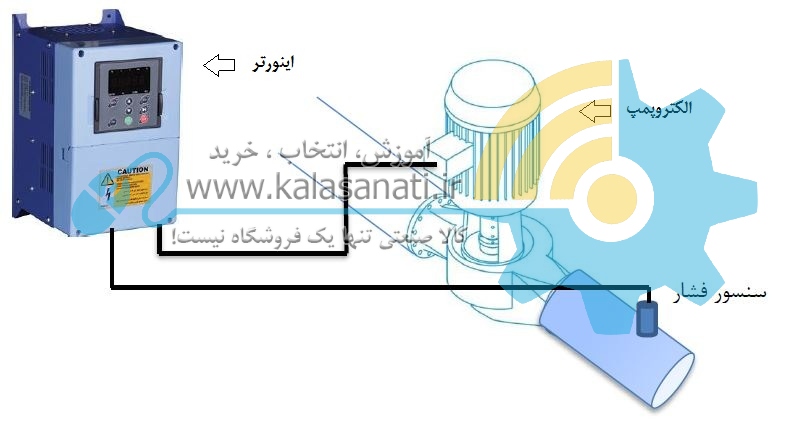

A: At times when water consumption drops, if the electropump speed remains constant, the pump output pressure will increase. Inverters are generally used to control the outlet pressure and pump speed during the day. To do this, a pressure sensor is installed at the pump outlet and its signal is transmitted to the drive or inverter. According to the setpoint for the output pressure, the inverter changes the electropump rotation and adjusts to the pressure required. The following image shows this system.

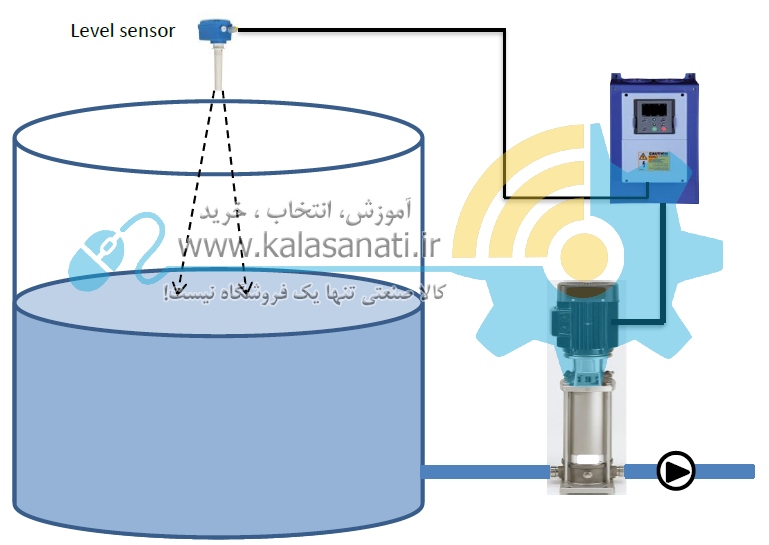

How is it possible to keep the water storage tank level constant?

A: The drive or inverter pumps can be equipped with a sensor called Level Sensor . There are two ways to keep the tank surface firm. The first is when the water is pumped into the tank and the second is when the water is pumped out of the tank and the surface is kept constant. For both modes, the Level Sensor with inverter can be used. The following image shows how to use this sensor.

What is Flywheel?

Answer: The flywheel, flywheel, or flywheel is a cast iron and heavy wheel used as an angular torque saver. In fact, flywheel will resist sudden changes in rotational speed in the shaft and will cause the electromotor shaft to stand at a steady speed over time.

How do they prevent ram blow after centrifugal pump?

A: To prevent the ram from occurring, it is recommended to hold the throttle valve before starting the centrifugal pump and to open it slowly after starting the pump to prevent sudden changes in speed. It is also advisable to shut the throttle valve slowly before turning off the pump and then turn off the pump.