Single Phase Electromotor

Alternating current motors are manufactured as single-phase and three-phase electromotors. Single-phase electromotors are often used for domestic purposes or in small-scale industries where single-phase electricity is a single-phase electromotor, but three-phase electromotors are more widely used in industrial applications and are manufactured at low power up to several hundred kW. The internal structure of the single-phase electromotor and the three-phase electromotor are approximately the same. However, the single-phase electromotor sometimes uses a centrifugal switch that is not used in the three-phase electromotor.

Due to the extra equipment, single-phase motors are more expensive and expensive than a three-phase electromotor, and have less power than a similar three-phase motor and have a lower power factor than a three-phase motor. For these reasons, single-phase alternator is less commonly used in large industries, but as most small-scale workshops continue to use single-phase power, single-phase electro-motors are still widely used.

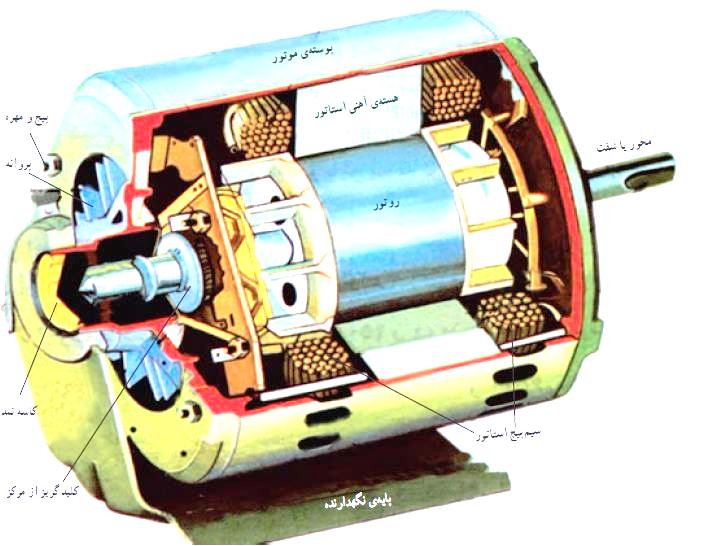

The various components of a single-phase electromotor are shown in the following image:

Frequently Asked Questions

Better single-phase electromotor cast iron or aluminum?

A: In general, cast iron shell is more robust, corrosion resistant and more durable but for use in tropical and hot places, aluminum shell electromotor is recommended and cast iron electromotor is more applicable for cold regions.

What are the uses of a single phase electric motor?

A: Lathes alternator, industrial fan electromotor, blower alternator, washing machine, dishwasher, dryer and laboratory electromotors are generally single phase and also series with industrial gearboxes for light lifts, conveyors and other properties A low-frequency alternator is needed.

What causes the electric motor to cool rapidly after ignition?

A: The main reason for the overheating of the alternator is the overload on the motor. Given that the cross section and coil circumference of each electromotive is designed for a particular mechanical power, if excessive load is applied to it, it is rapidly heated due to the discrepancy between the alternator power and the incoming load, and the probability of the motor being burned is high. goes. Therefore, the load should be reduced and the electric motor should not be used as a permanent alternator.

What is a single-phase electromotor?

A: Alternators are primarily used as industrial and even household mechanical actuators. The most common of these types of alternators is known as alternating current or AC induction motors , which is suitable for use in almost all related tasks.

What are the advantages of AC alternator over other electric motors?

A: To choose an electric motor and decide to buy and use it, we need to be aware of its advantages and disadvantages. The AC motor also has the benefits of making it more convenient to buy. Low installation costs Due to the ease of installation, the affordable price of ACalternator , easy connection to a power supply such as single-phase and three-phase power, as well as low maintenance costs at the time of use are among the main advantages of this electric motor. Is counting.

What is the difference between AC induction motors and DCalternators ?

Answer: AC induction motors are designed to be simpler than DC DC motors, but the two features of the AC induction motors make for a deeper and more comprehensible understanding of the design and specification of this motors. . These two features are: 1- Control of rotational speed of electromotor output shaft 2- Control of electromotor torque

What is a stator and rotor in an electric motor?

Answer: Different electromotors as well as AC induction motors have two main parts:

1. Stator: which is the constant external part of the alternator .

Rotor: This is the part where the engine rotates.

In the electromotor, there is a gap between the stator and the rotor, expertly and precisely. Usually, all types of electromotors and ACinduction motors use a rotating magnetic field to rotate the rotor.

What is the important difference of a three-phase AC single-phase AC induction motor ?

A: In other alternators , the magnetic field is the local rotor in which the rotor rotates, but in the three-phase electromotor it is the stator that normally generates the magnetic field because of its three-phase power supply.

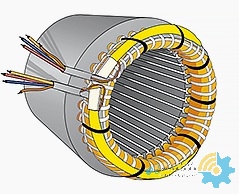

Describe the structure of a stator?

A: Several thin layers of iron and silicon alloy, which are located around the wall of a dynamo , create a stator. The core of a stator also has parallel grooves that are filled into the grooves by coil-coated wires. In the stator structure, its parts are stuck together like a hollow cylinder head. Stators have coils surrounded by kernels, which gives the structure of the kernel a magnetic magnet to work with the power supply.Stator coils play an important role in their operation because they are directly connected to the power source. Therefore, the number of poles in an AC induction motor depends entirely on how the coils are connected. If the coils are connected to the AC power source and theAC power supply is installed This results in a rotating magnetic field.

How is the rotor made and working?

Answer: Consider several sheets of non-conductive steel, including copper and aluminum rods, this structure being the structure of a rotor in an AC induction motor . The squirrel cage rotor is one of the common types of rotors whose structure is such that the aluminum and copper rods are mechanically and electrically bonded together at the end by rings. Since the rotor is a simple, robust cage structure, most induction motors use this type of rotor in the alternator structure .

What is the reason for naming squirrel cage rotors in electromotors?

Answer: Usually any name on a device has a cause or background that the squirrel cage rotor does not exemplify. This rotor is called a squirrel cage, with its cylindrical multi-core core having parallel slots and embedded in each slit of copper, aluminum, and alloy conductive rods. These rods are permanently short-circuited by rings at their ends. Similarly, they place a squirrel in a cage, and the squirrel will rotate the ring by moving and running on it. Because of the similarity of these two devices, they are called squirrel rotors.

How do the stator and rotor teeth fit into an electromotor?

A: There are two main parts of a alternator , the stator and the rotor, which are important for how they are positioned. The rotor teeth must be positioned so as to stand against the stator teeth. This arrangement is due to direct magnetic absorption that is produced only when the rotor and stator teeth are opposite.

How to mount a rotor rod of an electromotor? How is the force applied to a rotor?

A: The bearing is the part of the rotor that is mounted at the two ends of the rotor axis; the bearing always causes one side of the rotor axis to move higher than the other. Sometimes some motors may run in the opposite direction They have a secondary axis for transmission of axis position and speed for power transmission.

What is the space between the stator and the rotor?

Answer: Since there is magnetic induction between the stator and the rotor and the energy has to be transferred from the rotor to the stator, there is always a gap between these two important parts of the electromotor.

How does the rotor of an induction dynamo perform?

A: The rotor in an electromotor, like any other magnetic device, requires a force to rotate or move, and here the force required to rotate is generated by the torque generated by the rotor. Usually the general rules of rotation are the same for all rotors and do not depend on their type.

On what basis are induction motors classified?

A: The induction electromotors are generally classified according to two important parameters, the parameters referring to the number of screws that are the stator coils. The parameters are different types of electric motors, electric single phase electric motors , three-phase requirements.

What are the features of a single phase induction motor and how does it work?

A: Usually the most commonly used electromotor is single phase AC induction motor . The induction single-phase electromotor, according to its designation, has only one coil or coil and supplies its own single-phase alternating current.

Rotors housed in single-phase induction motors are usually cage type. These electromotors are not capable of automatic start-up. When asingle-phase coil or alternator coil has an alternating current to connect to its power supply.

How does a single-phase electric motor start up?

Answer: The device that launches a single-phase induction motor is called a starter, which is just an extra coil in the stator. This coil, also called the starter coil, can have a centrifugal switch as well as a series capacitor.

When the voltage is in the power supply, the current in the main coil due to the resistance in the main coil will drastically reduce the main supply voltage and consequently the voltage will become current. The current in the starter coil then converts to a supply voltage due to the starter resistance and helps to increase it.

When does the start screw stop moving?

A: The screwdriver is an important part of a single phase electric motor that will stop somewhere when the electric motor has reached 75% of its permissible speed, which is to stop the pedal by a centrifugal switch.

How do magnetic interactions occur in a single-phase electromotor?

A: In the single-phase electromotor of the main coil and the starter device, which comprises the two parts of the auxiliary coil and the capacitor, they interact with the magnetic field. Together, they create an output field that initiates the rotation of the electromotive axis from that field.

Under what circumstances is it permissible to use single phasealternator ?

Answer: Usually a single-phase electromotor is only intended for use in applications of less than 3 horsepower, although this type of electromotor has been found to be used on a larger scale, which is only possible under certain circumstances.

How is the design and structure of AC induction motors with broken phase?

A: The broken phase induction motor is known as the induction starter and induction function. This type of electromotor, like single-phase, has two main screws and a starter.

In comparison, these two screws can be said to be wrapped in thinner start screws and in shorter rounds for greater resistance to the main screw. The other difference is the starting screw with the main screw which is positioned in a position which is quite different from the main screw. This angle causes the alternator axis to rotate . The main screw has thicker wires that always keep the axle ready to rotate.

How to start a broken phase electromotor?

Answer: A broken-phase induction motor requires a high current to start, usually 700 to 1000% of rated current, whereas the starting torque is only 100 to 175% of rated current, as well as the maximum torque produced. Something is about 250 to 300% of the nominal stream.

Here are some of the important uses of a broken phase induction electromotor.

A: Electromotors for small abrasives, alternators for small fans and fans, and other devices that require low starting torque and power requirements? until the ?/? Horsepower is one of the important uses for a fractured phase induction motor. It is important to note that these electromotors are not suitable for applications requiring continuous shutdowns or high torque.

What is a single phase AC motor with capacitive starter and how does it work?

A: To get started, a broken phase induction alternator requires between 700 and 1000% of rated torque current which is usually unavailable, which is why this electromotor has trouble getting started. To correct this problem, they add a series capacitor that gives rise to a new electromotor called capacitive starter induction motor. A series capacitor induction motor, like a broken phase induction motor, stops the coil start by switching its centrifugal switch when the electric motor has struck 75% of its allowable speed.

How to design single phase AC electric motor with permanent split capacitor?

A: In this type of alternator a series of capacitors is permanently attached to the starter coil. This structure is designed because the starter coilacts as a coil coil until the electromotive axis reaches its rotational speed. The main performance capacitor must be capable of continuous, non-stop operation and failure, so this capacitor cannot generate its own starters equal to one kilometer of capacitive starter because the starter torque of a permanent, very low capacitance electromotor is about 30 to 150. % Torque is a name.

How to start a single-phase permanent capacitor electromotor?

A: The current required to operate a single-phase induction alternator with a very low permanent capacitance is as high as 200% of rated current.

What are the Uses and Benefits of a Single Phase Electromotor?

Answer: An induction single-phase electromotor is suitable for applications with high-speed off-switch periods. These types of electromotors also have more special advantages, which we will address in a few important ways:

for example, the type of design of these dynamos can be easily modified for use with rotational speed controllers. They can also be designed for optimum efficiency and high power factor at rated load. Single-phase electromotors do not have centrifugal switches, so they are the most reliable type of electromotor available.

What are the factors associated with single-phase electromotive use?

Re: User type alternator for single-phase induction is different and depends on how they are designed. Depending on the design of this electromotor, they can have a variety of uses, including: fan motors, blowers with low start torque and temporary work periods such as garage door openers.

What are the components of a single-phase AC starter motorwith a capacitor?

A: This electromotor needs high torque to start its operation, so it has a starter capacitor in series mode with a small screw. Capacitor starter motor Like a single-phase permanent capacitor motor, in addition to the series capacitor, it has a permanently working capacitor and auxiliary coil (after the alternator starts running).

Do you also supply single phase electric motors in Mashhad?

A: In Mashhad, free shipping is available for purchases over $ 3 million.

What are the brands that produce single-phase electromotors in Yazar?

A: Single Phase Electromotor Electrogen is one of the brands of Iranian single phase electromotor. Types of Chinese single-phase electromotor brands, single phase single phase electromotor and European single phase electromotor are the most widely used dynamics in the world today. Kajeli single-phase alternator is one of the most popular brands of Chinese engine in Iran.

Is there a single-phase cast-iron electromotor?

A: There is a single-phase cast-iron electromotor and a single-phase aluminum shell electromotor in Yazar, Iran. Depending on the type of electromotor shell, the power of the electromotor and other characteristics of the single-phase electromotor price vary.

Where can I get a single-phase electric motor?

A: On the Industrial Commodity site, we try to keep the single-phase alternator price up to date and provide an up-to-date price of the electric motor. The price of a single phase motor can be obtained from sales experts.