The industrial vibrator, or body vibrator, is one of the most widely used components in many industries. Contact sales experts for a vibrator price list and vibrator catalog.

The types of systems in which vibration of the industrial body is used are divided into two. Free-swing systems and resonance-limited oscillation systems. In free systems, both linear and rotational methods can be used to vibrate. In a linear free-swing system, two identical vibration motors with identical technical parameters moving in opposite directions should be used.

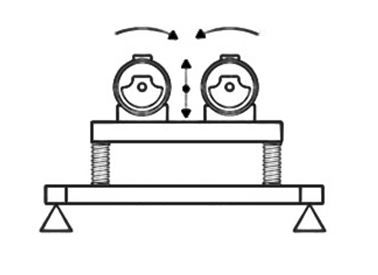

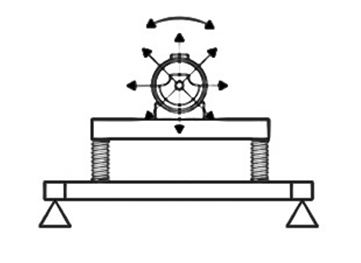

In the linear free oscillation system, the vibrational force is reciprocated and this causes the linear motion to be called a one-way vibrator system. But in a rotary vibration system, a number of vibration motors are used, which are located in the center of the table and generally closed below the table. The vibrational force in the rotating vibrating system is uniformly generated at all 360 degrees. The following images show the linear and rotary body vibration system.

But the question that arises is in which real-world linear and rotary vibration system is used in the industry? Vibration of the body with a linear system is generally used in dischargers, measuring instruments, transmitters and conveyors or the same conveyer. This is while the rotary system is used in filters, cement silos, etc., filters and simple devices to separate materials.

Proper adjustment of weights in the vibration engine is almost straightforward, but it should be noted that proper adjustment has a great impact on the performance and life span of the components and equipment to which the engine is attached. The market is generally used for vibration of the body with the names of vibration motor, industrial vibration, three phase and single phase vibrator, industrial vibrator and vibration table.

In a typical vibration, the vibration force is applied by mounting two lame numbers on either side of the shaft of an engine. It can be 3000 rpm, 1500 rpm, 1000 rpm or 750 rpm. The vibration of the body will also be adjustable. In fact, the vibrational force in an industrial vibrator depends on the weight of the rotating mass, the distance from its center of gravity to the center of rotation, and the rotational speed.

If the vibration weights of the body are not the same at both ends of the vibration, it will be irregularly functioning and in addition to the vibration life of the body, it will not achieve proper performance.

In many cases, given the small size of the vibration motor, it can be converted to a single-phase vibration motor using a capacitor on the vibration path. Get in touch with sales experts for free advice on buying industrial vibrators.

For the price list vibrator with experts please get in touch.

To get the catalog vibrator with experts please get in touch.