What is a gear pump? The gear pump, which is manufactured in both outer and inner gear types, is considered to be a positive-displacement pump group and with a constant amount of rotation each time the gear is operated by the gears Shifts the fluid. Refer to the tutorial videos page to learn how the gear pump works.

Gear Pump Training Video

Frequently Asked Questions

Frequently Asked Questions

What is the solution in a gear pump or throttle to prevent pump output?

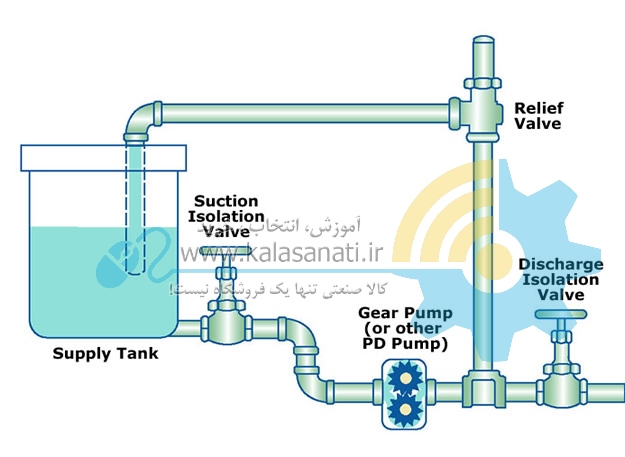

A: The gear pump is a series of positive displacement pumps and if it is blocked on the way out, the pump or system immediately disappears.Therefore, at the pump outlet, a pipe is inserted to return the pumping fluid to the tank, which is called fluid bypass. The concentrated pump must also be located so that it is always inside the pump filled with fluid. To do this, the tank is generally above the pump. The following figure shows a pumping system with a gear pump or a concentrated pump.

What are the benefits of an internal gear pump?

Answer: Internal gear pumps have the following advantages:

Internal gear pump has only two swivel members, has a smooth, pulse-free flow, is suicidal, it can operate dry for a short time, gear pump features Because rotation is two-way and filling and discharging the tank, gear pump maintenance is easy and is very suitable for high viscosity fluids.

What are the limitations of the internal gear pump?

A: The internal gear pump also has its disadvantages and limitations along with its significant benefits. Limitations of these types of pumps include the low and medium operating speed as well as the low and medium pressures.

What are the uses of internal gear pumps?

A: Internal gear pump is used for pumping thin liquids such as solvents, oils, etc., as well as pumping thick fluids such as asphalt, chocolate and adhesive pump. Other applications of internal gear pumps can be used for pumping oils, industrial lubricants and fuels such as liquefied petroleum gas, gasoline, diesel, petrol pumping, crude oil, etc., all kinds of resins and polymeric materials, alcohol and all kinds of solvents Notes, asphalt pumping, bitumen, tar, polyurethane foam and stainless steel gear pumps for foods such as chocolate and peanut butter, dyes, inks and seeds colors, and soap pumping.

What are the components of an internal gear pump?

A: Internal gear pumps include four body parts, gear, bush and shaft. The body and gear are generally cast iron, bronze, stainless steel, polymer (teflon) and alloy steel, bush made of carbon graphite, bronze, silicon carbide, tungsten and ceramic carbide, and alloy steel shaft, stainless steel.

What are the uses of a gear pump?

A: Gear pumps are commonly used for pumping oil in power transmission systems, hydraulic systems, and machine tools. Gear pumps can control the amount of discharge by considering the distance and interior structure so it is possible to pump a specific amount of fluid such as different types of fuels, polymers, chemical additives, Used acids and bases.

To what extent are external gear pumps available?

A: External gear pumps are available in two different sizes; small size external gear pumps generally operate at 1450 or 3000 rpm and large sizes at 650 rpm.

What are the benefits of external gear pumps?

A: External gear pumps have advantages including: high speed, high pressure, quiet and quiet operation, relatively cheap and inexpensive price, low sensitivity to dust.

What are the main limitations of external gear pumps?

A: In external gear pumps, the pumping fluid should not contain corrosive solid particles, as this will cause the gears to corrode and cause serious damage to the pump.

What is the structure of external gear pumps?

Answer: An external gear pump consists of five body parts, gear, shaft, bushing and sealing. Body and Gear from Cast Iron, Stainless Steel, Cast Iron, Polymer (Teflon) Polymer and Bronze, Shaft Material from Steel, Aluminum, Ceramic Alloy, Bush Material from Carbon, Bronze and Stainless Steel Silicon Carbide and Sealing Material from Packing, Mechanical is flood and magnet.

What is the reason behind the design of the gear pump and what features should the pumps have?

A: The main reason for the design of gear pumps is the use of these pumps for pumping and pumping liquids of high volume and high pressure. These pumps pump liquids that do not have any solid, corrosive or impure friction material and also have lubricating properties.

What are the uses of gear pumps?

A: Gear pumps are mostly used for pumping lubrication systems of engine, fuel, gas oil, molasses pump, pulp and other self lubricating liquids used in the industry. These pumps are also used for lubrication and cooling systems for various machines (machine tools, combustion engines, etc.) with low pressure.

What is the design of gear pumps?

A: Gear pumps have two propulsion gears that rotate inside the shell. When the gears are rotated, the gears hold the fluid in the suction section between the pump housing and the gear crown and carry it with them to the pump discharge section, where the gear is driven by high pressure to the discharge branch. he does. In gear pumps there are two actuator shafts which are located on the actuator shaft on the actuator shaft and on the actuator shaft there is a spur coupling. On both sides of these axles there are lubricant-supported retaining caps that are prevented by the pumping (graphite yarn) and graffiti-retaining liner preventing the pumping fluid from leaking around the actuator axis .

What pump is used to pump hot and cold liquids?

A: Gear pumps are generally used to pump thick fluids at temperatures of 80 to 300 degrees Celsius.

What kind of safety equipment is included in gear pumps?

A: Gear pumps are positive displacement pumps and if their outlet valve is closed in addition to damaging the equipment at the gear pump outlet, the pump itself will be damaged. Therefore, the output of these pumps uses bypass, which acts as a safety valve. If the pump operating pressure exceeds the specified permissible value, the valve is opened and the pumped fluid is pumped through the bypass pipe to the suction part of the pump.

How does the gear pump operate?

A: The purpose of the design is to design a direct coupling gear pump with the lecturer on the chassis. The connection to the gear pump is generally made by an electric motor and a reducer gearbox located between the motor and the pump. In a rotary gear pump, the axis of rotation is simply driven by the torque arm and the radial torque in the initial movement of the gear pump is predetermined.

Is the gear pump right or left?

A: The gear pump can be used right or left round.

What are the general rules of speed in gear pumps?

A: Normally, lower turnover speeds are for higher density materials and less lubricating liquids . Also, pumps that have a low turnover rate are used when doing long work in the program. High circulation speeds are used for thinner liquids whose density is low.

What are the applications of gear pumps at different speeds?

A: The maximum speed of 1000 rpm in gear pumps for the lubrication and cooling oil and liquids with viscosity 40-10 used . The maximum speed of 750 rpm is used for gear pumps in their lubricating fluids having a viscosity of 30-30 150 . The maximum speed of 200-200 rpm is used in heavy liquids, oils, molasses pumps, pastes and other high viscosity fluids, and the maximum speed for steel and brass gear pumps is generally 500-200 rpm. In minutes .

What is a gear pump?

Answer: One of the types of positive displacement rotary pumps is the gear pump, which in this type of pumps on one side, at the contact point of the gear, the teeth that are rotating away from each other due to the relative vacuum of the fluid. It is pumped into the pump and then driven to the outlet.

What is the output of the gear pump?

A: Gear pumps must pump for a constant amount of fluid throughout their rotation. The output of gear pumps is uniform, alternating and pulse-free due to the interference between the gears and their drive mechanism. It happened.

What are the benefits of gear pumps?

A: Gear pumps can also pump high-density materials. In inlet and outlet gear pumps, they can be rotated by changing the rotation direction, which makes the fill pump tank without having to replace the fittings. Another disadvantage of gear pumps is their high efficiency in low rounds as there are no centrifugal pumps in the fluid flow path so no need to increase the friction to overcome the existing friction.

What gear pumps are suitable and for which liquids are they suitable for pumping?

A: Gear pumps are suitable for pumping high-density fluids, different fuels and oils, and on the other hand they do not seem to be a good option for pumping solids as well as liquids containing solids.

How many gear pumps are available?

A: Gear pumps are divided into two types of internal gear pumps and external gear pumps. The similarity of the internal and external gear pumps is the existence of a jog wheel and a drive gear in both of them and the difference. Pumps are a major difference between the fluid lock and the gear housing.

What is the Important Use of External Gear Pumps?

A: External gear pumps can control the flow rate depending on the distance and the internal structure, so one of the important capabilities of these pumps is to pump precise and calculated amounts of various fluids such as types of fuels, polymers, additives. Chemicals, acids and bases.

What are the uses of double-walled pumps or jackets?

A: Double glazed or jacket pumps are used to pump materials such as creams, chocolate, paste, glucose and marmalade as well as pumping high temperature industrial fluids.

What are the different components of a double-walled pump?

A: sex different parts of a pump or jacket bearing steel double Smanth SC , stainless S.s316 , gray cast iron GG25 , ductile iron GGG50 and is made of bronze.

What are the different types of sealing in double wall or jacket pumps?

Answer: Types of seals available in double-walled or jacket pumps include mechanical fluid cartridge, mechanical double seal, mechanical seal, graffiti thread and sealant.

What is the bearing on double-walled pumps or jackets?

Answer: Bearing in double-walled or jacket pumps is done in three types of bronze, carbon graphite and teflon.

What is the power transmission system for double walled or jacket pumps?

Answer: Power transfer in double-walled or jacket pumps is done in four ways: the gearbox coupling, the hydromotor coupling, the direct coupling and the coupling with the straps and straps.

When do we use helical pumps?

A: We use helical pumps when we want more capacity than gear pumps and also require a slower flow than simple gears. We know, however, that simple gears are capable of producing smooth flow.

What is the speed of the helical pumps?

Re: speed gear pumps with different large and small, like small fast gear pumps between rpm 1750 the rpm 3450 and quickly grew to gear pumps rpm 650 is.

Why External Gear Pumps Are Suitable for Hydraulic Use?

A: Usually, external gear pumps have low tolerance and shaft support and shaft support are provided in both directions, which can increase the capacity of external gear pumps to 200 psi / bar . These causes make the external gear pumps more suitable for hydraulic use than their other types.

What are the benefits of external gear pumps?

A: External gear pumps have advantages and disadvantages, including the following: The

first advantage we can point to in external gear pumps is the high pressure in these pumps. An external gear is less susceptible to dust. Gear pumps can be easily designed and manufactured with a variety of materials. The amount of gear pumped into the shaft is very small.External gear pumps operate with the lowest noise level and also the speed of operation of gear pumps is very high.

What are the disadvantages of gear pumps?

Answer: Among the disadvantages of gear pumps can be mentioned three things are: No need for comprehensive materials in the fluid because they will corrode the gear, gear pumps have very low impedance which is difficult to build This is the type of pump that is located in the gear pumps in the fluid.

What are the uses of external gear pumps?

A: External gear pumps are used in the pumping of acids and bases that are made of stainless steel or composite construction. External gear pumps can be used for pumping chemical additives, for volume transfer. Low gear external pumps are a good option, as well as other types of external gear pumps, such as hot oils and oils, industrial lubricants, fuels, mixtures and chemicals, and hydraulic oils.

How is the structure of external gear pumps?

A: Gear pumps are made up of different parts, each of different gender. Gear steel, stainless steel, PTFE and composite ( PPS ) is a steel sealingmagnet, mechanical sealing and packing, gender Bush of carbon, bronze, stainless steel, silicon carbide, steel body with iron, cast iron, steel, Stainless steel, composites (PPS, ETFE) and shaft are made of steel, aluminum, alloy steel, ceramic.

What is the particular problem with external gear pumps?

A: In external gear pumps, a phenomenon occurs when the fluid returns to the suction opening; this is called internal leakage. The problem with external gear pumps is due to leakage, which is a result of reduced pump discharge.

What are the factors affecting the internal leakage of gear pumps?

A: There are several factors contributing to the internal leakage of gear pumps, for example: Internal leakage in gear pumps is inversely proportional; there is a direct relationship between the leakage in the gears and the gear pump housing and internal leakage. The higher the viscosity of gear pumps, the more the internal leakage increases, and the last difference in pressure between the inlet and outlet pumps is directly proportional to the internal leakage rate.

What is the most common use of gear pumps and why?

Re: gear pumps can be used in different cases, but they are the most widely used for simple systems with pressure relatively "low mpa) 14-18Ya 180-140 ( time Bashd.dlyly for which there is a gear pump O very simple, reliable, relatively inexpensive and have the least sensitivity to dust.

How do gear pumps work?

A: In gear pumps with gears rotating, the gears in the suction section are point BThis is where the forced discharge of liquid approaches, where a vacuum is produced at this point, and the oil pumping continues through the gaps between the gears. Oil in the enclosure continues. It is transmitted to the compressor section of the pump and then driven out of the gear due to the gears being locked and driven to the pump outlet. In the gear pumps the gears move overhead. This causes the oil that is pumped into the pump to no longer return to the suction part of the pump, which results in the oil first sucking out of the pump. The pressure side is transmitted and then transmitted along the part where the gears are installed. Determine the amount of pressure required in the pressure part of the pump depending on the resistance in the system. The resistance level is related to the hydraulic motor and cylinder parts.

What to do in gear pumps to prevent bubbles from sucking?

A: In order to avoid gear pumps and bubble liquid pumping, the amount of pressure required in the suction part of? /? until the ?/? Load orKpa ?? - ?? Do not exceed and pressure below atmospheric pressure; minimum absolute pressure? /? Times or Kpa ?? is.