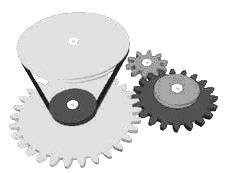

Simple gear is the most common type of gear. Simple gear teeth are parallel, so they are used for power transmission in parallel shafts.Simple gears have little noise at work and at medium speeds, but at high speeds this noise is annoying and increasing. In this type of gear, the teeth cause the sudden transfer of loads from one tooth to the next, resulting in sound and vibration. It should be noted that the contact of the teeth in simple gears is more rolling, and only at the beginning and end of the tooth involvement is the slip .

Frequently Asked Questions

What does an industrial gearbox do?

A gearbox is responsible for transmitting power and moving from one rotating shaft to another by engaging the gears together. They are called smaller pinion gears. The ribs have different types of mechanical structure that are divided into 8 types .

What are the types of gears in terms of differences in mechanical structure?

Answer: The ribs are divided into eight types in terms of mechanical structure: simple gear, spiral gear, spiral cone gear, coil gear, annular gear, twig gear, conical gear and hypoid gear.

What lubricants are used in plain gear?

A: In plain gear, lubricants are usually used with mineral oils containing oxidizing and anti-rust inhibitors. Low viscosity lubricants are used in high speed and low load gearing .

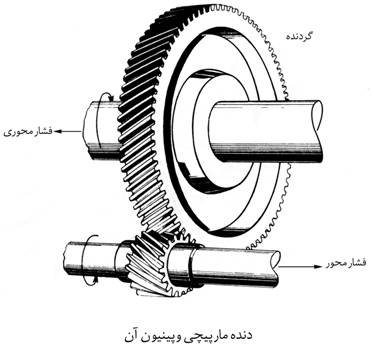

How do spiral gears work?

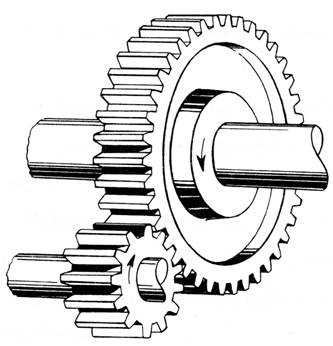

A: The helical gears have tilts to the gear axis. In spiral gears, the teeth intersect at a center angle of rotation, which causes the load to move more smoothly during one tooth (gradual tooth involvement), thereby reducing the amount of noise. To be. Spiral gears produce less noise and vibration than simple gears . The amount of charge on the helical ribs is distributed between several teeth and, as a result, the wear decreases. The angular incision of the spiral gears causes the pressure resulting from the involvement of the teeth of these gears to be seen as axial pressure along the gear axis. This type of operation requires that the axle bearing absorb the axial pressure applied and cause the gear line to remain unchanged . The use of a helical gear is similar to that of a simple gear, although these gears may also be used to move between two axial strings .

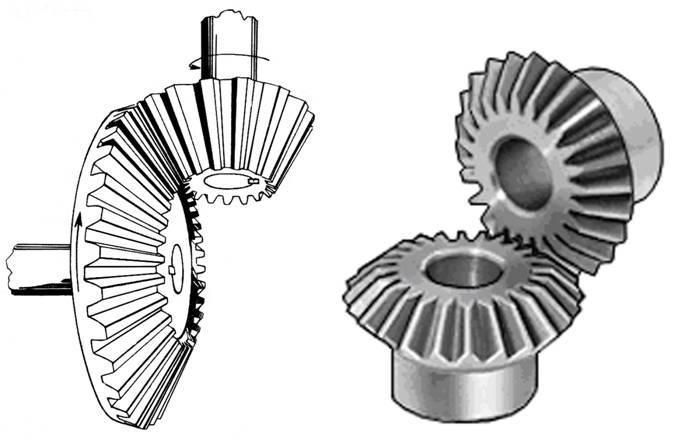

How does the cone gear work?

A: When the shafts are not parallel, the most likely type of gear used is the conical gear. These gears are used to transmit motion between axes that are at intersections. The angle of intersection of these axes is usually 90 ° C but may increase by 180 ° C. If the gear involved is identical in size and its axes are at 90 ° C, they are referred to as Persian gear.

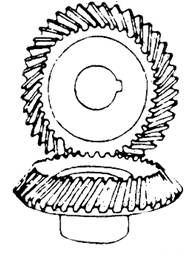

What is the basis of the operation of the spiral cones?

Answer: If the spiral teeth are cut in a curve, they are called spiral cones. The performance of the spiral cones is faster and faster than that of straight cuts. In spiral cones, the teeth are like arcs. These gears reduce noise and vibration .

Spiral conical gear

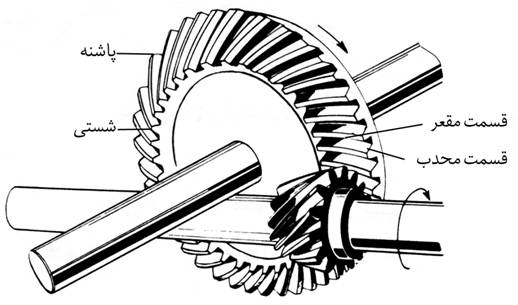

How Does Hypoid Gear Work?

A: Hypoid ribs are very similar to helical conical ribs, except that the center of rotation of the axes are not intersecting and the pinion axis is not capable of intersecting the large ribs. The most used in this type of gear is in the car differential . Hypoid ribs are a combination of rolling gears with high indentation pressure on spiral conical ribs as well as sliding gears of coils. The lubricants used in these gears must contain lubricant and anti-corrosion additives so that the gear can withstand high tooth pressures and high friction rates.

How is Hypoid Gear Used in Hard Conditions?

A: Hypoid ribs due to their different appearance, under severe operating conditions (rolling movements with slip and high tooth pressure) and heavy loads, cause an extra slip between the ribs, resulting in high friction and high slip speed. Are. Hypoid ribs are severely prone to scratches and strains, so oils containing large quantities of scratch-resistant and scratch-resistant additives are required .

Hypoid gear

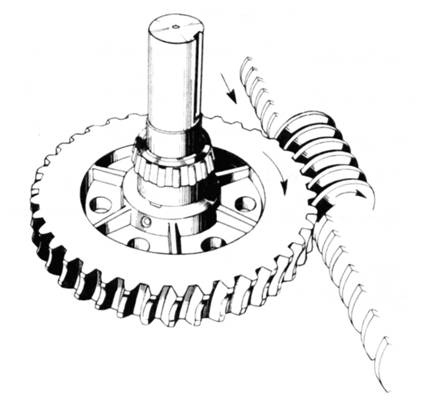

Describe the function of the coils.

A: The coils have a screw or spiral groove that moves in the opposite direction of a gear. How they work is like a screw. The relative motion between these gears is in most cases slippery . Coils are different from other gear due to the dominance of sliding motion between the wheel and the cochlea, due to the rolling motion. The sliding motion of the coils causes the lubricant to form on the gear surfaces. If the pressure on the coils is evenly distributed and metals such as bronze with a very low coefficient of friction are applied, it will be suitable for the manufacture of gears with hardened steel coils .On the outer ribs, heavy loads or pressurizing oils should be used because of the high slip motion during load transfer. These gears require a full layer of lubricants and heavy blended oils to create effective lubrication to prevent metal-to-metal contact with increased lubrication and lubricant strength.

Coil

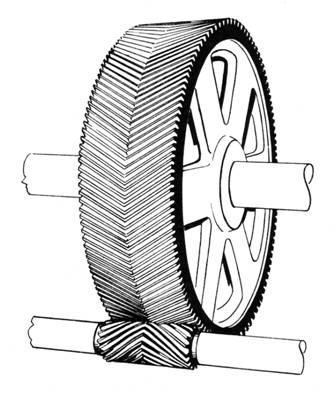

What is the structure of the ribs and what are they used for?

Answer: If two helical ribs are opposite (opposite) to their teeth, a twisted rib will be created. The design of the twisting ribs is such that they remove the axial loads (orientation of the ribs to each other is necessary to ensure proper alignment of the teeth) .

Twigs

How is the ring gear working?

A: In annular gear, the shape of the teeth is very similar to that of helical and simple teeth, but unlike that of spiral teeth, in the annular gear, the placement of the teeth within the system. How the teeth work and of course the type of lubricant required for these gears is the same as the spiral gears .

Annular gear

What are the characteristics of gear oils?

A: A layer of oil is created on the contact surfaces of the gear teeth, which minimizes or prevents metal-to-metal dry contact .

All lubricants must have characteristics such as high pressure, compatibility with the bowls, anti-rust properties, convenient gear replacement, power transmission and lubrication