Types of pumps

Pumps are of different types but the most used pump in the world are centrifugal pumps. Here is the complete description of the centrifugal pump:

Centrifugal pump or centrifugal pump

Centrifugal pumps or centrifugal pumps are the most widely used pumps. The simplest type of centrifugal pump consists of a propeller that is attached to an engine by any axle or any device that can rotate it. The fluid enters the suction port of the pump and exits the thrust manifold in the spiral direction, which increases in the cross-sectional area, with the force applied to the pump. The centrifugal pump impeller has several types. Closed impeller is one of the most common type of impeller in centrifuge pump. The propeller blades are bent backwards. In other words, by observing the pump impeller, the direction of rotation can be detected.

Radial pumps, which are divided into simple or coil pumps and the Diffiuser Pump diffuser , are one of the most widely used types of centrifugal pumps. Mixed Flow Pumps and Axial Pumps are other types of centrifugal pumps.

The second category of centrifugal pumps is the Mixed Flow pump . In this pump, the flow is directed in the center of the impeller and its outlet is neither in radius nor in axis direction. In other words, the pump is both centrifugal and pushing the thrust direction. In floating-impeller pumps, the Mix Flo impeller is superior to the simple impeller because it eliminates the thrust force more easily.

Axial pumps are other types of centrifugal pumps. In these pumps, the current enters the axis in the same direction and exits in the same direction. Performance at this pump is exclusively by pushing fluid to the outlet. These pumps have very high discharge and discharge and low altitude. For example, an axial pump may not hold up to 10 meters but can carry 10,000 liters per second.

Frequently Asked Questions

How is the axial force transmitted to the floating electropump?

Answer: The axial force in a conventional centrifugal pump is transmitted through bearings that are capable of absorbing axial force, but in the submersible pump, the axial force of the submersible pump is tolerated and transmitted.

What relationship is used to reduce longitudinal pressure on the long transmission line?

Answer: Two calculus known as Darcy Weisbach and Hazen Williams are used to calculate the drop in pipes. For a high-production transmission line, a very simple way is to use the Hazen Williams relation. In this regard, with the values of pipe length, pump discharge and inner diameter of the pipe, it can be easily calculated the pressure drop. In all the fluid and hydraulic pamphlets the calculations are given.

Why use more centrifugal and centrifugal pumps?

A: These pumps have two very important advantages: 1- There is a discharge pump at the Dubai Continuity Center and the flow is uniform.2- They are obstructive at pump outlet. And in the short term the pump will not be damaged.

What to do to turn off the pump automatically?

A: In the centrifugal pump, by pushing the thrust path, the pressure is raised and by placing a pressure gauge on the pump outlet, commonly known as a pressure gauge of 4 to 20 mA, giving the operator an alarm or using a return valve, When the thrust path is closed, move the fluid to the suction path (bypass fluid bypass ). However, it should be noted that the rotation of the water in this closed loop causes it to warm up.And it's better to move to the suction tank than the suction path.

Which electropump produces more head?

A: Among the centrifugal pumps, the type of radial that pumps water radially receives much head but with less discharge.

How does a thrust pump evolve at a pump?

In these pumps, due to the shape of the impellers, the pressure in the impeller's eye area must be low until water enters the impeller and the pressure behind the impeller is high. This pressure difference on both sides of the impeller will create an axial force on the impeller and push the impeller toward the suction nozzle. This force is neutralized in small pumps by ball bearings, and in vertical vertical pumps, it is neutralized by round foils.

What is the gap between the impeller and the suction pump openings?

The amount of this standard defect is not specified and many factors such as the amount of drainage or discharge of the pump, the amount of vibration permitted by the pump, how to install the impeller ( Overhang is either one-sided or coaxial), both sides of the pump shaft are taken by the bearings. Or is free and depends on several other parameters and is generally determined experimentally by the pump makers.

In the two sucker propellers, how much is the clearance on each side?

There is no specific relationship to the propulsion in these impellers and is generally determined experimentally.

Is the pressure in the coil pump higher in the suction opening or the thrust opening?

The pressure in the thrust opening is higher, and this pressure, also called radial pressure, damages the pump shaft and shakes the electromotor and pump assembly and can tilt it.

What is the difference between horizontal and vertical floor pumps?

A: In terms of functionality, the two are very different, but in appearance, in the class horizontal pump, also known as the VKL pump , in their very large pumps known as the NC pump , the balance pistons or ball bearings in the part Used behind the impeller , the engine is located at the bottom of the Vertical Class Vertical Pump, also known as the Shaft and Sheath Turbine Pump.

Which system is used to seal the pumps?

A: Mechanical seal and packing are generally used in the staging box or sealing chamber to seal the pump. For example, in KSB pumps there are two rows of packing and one row of lanterns where water flows to cool and then three other rows of packing.

Flushing at pumps in how many ways?

A: There are generally six methods for flushing mechanical seals. The mechanical seal housing is small. By rotating the shaft, the rotating parts of the mechanical flood will be rotated and heat will be generated in the mechanical flood chamber. The two levels of Stationary Faceand Rotating Face are separated by a thin layer of lubricant, which is usually a pumping fluid. If the lubricant somehow gets out of the surfaces, then the Stationary Face and the Rotating Face will be in direct contact and will damage the pump despite the heat generated.Oering is one of the most sensitive parts of mechanical flooding and with the increase in temperature these damaged parts and Ooring failure will result in mechanical leakage.

What is the best measuring tool for Dubai?

A: The industry either uses meters and flow meters (which today have a special place in magnetic meters) or measures the flow of water from the Dubai overflow. Venturi meters, Orifice and other Dubai measuring devices are also common.

What are the types of control valves in Dubai?

A: There are basically four categories of milk to control Dubai. Manual valves, hydraulic valves, mechanical valves and electric valves.

What is the main reason for mechanical flood damage?

Answer: Mechanical flood damage is generally due to the presence of particles in the pumping fluid. In submersible pumps, if mechanical flooding is at low levels, due to the presence of pebbles and gravel in the well, mechanical floods will soon break down and floods should be placed at high levels.

What pump is used in areas where the surface difference is low and the slope cannot produce the required pressure?

A: In cities with a slope, tanks are used to supply pressure, and in cities with a slope, they use a pump booster or pressure pump. In this system, one or more pumps are connected in series, depending on the amount of time used to turn the pump on or off. The pumps are switched on and off using the pressure gauge in the thrust path. For example, in the northern provinces where there is no natural disaster, booster pumps are used.

How do they control Dubai in pumping systems?

A: Dubai is generally controlled by valves in pumping systems. Sliding valve (for use in the water-lid networks rubber-coated valve and in hot water conveyors, usually brass and cast iron body), Grout valve and spherical valve and butterfly valve are all types of valves.

What is the basis for choosing a circulator pump?

A: In cooling and heating plants, circulatory pumps are generally used to rotate water in the system. These pumps only need to overcome the pressure drop in the track and have no role in the height drop. In other words, the more water that goes up the system, the more pressure it generates and returns.

We have installed the pump in the well but it does not meet the expected pressure after commissioning and the outlet pressure is much lower, what is the reason?

A: It is very likely that the pump rotates in reverse and we need to reverse the rotation and control the pressure by shifting the phase. If the pressure is increased, the pump rotation is correct and the pump is working properly and other factors should be considered if the pressure is lowered.

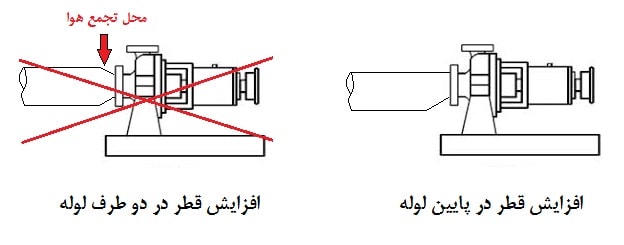

The catalog introduces a maximum inlet pump of 2 m / s, the inlet pipe to the pump is 5 inches and with this pipe will increase speed, what is the solution to slow down?

A: In pipes, the velocity and diameter of the tube are inversely correlated, so increasing the diameter of the tube can reduce the velocity in the tube. The point to note is that the increase in tube diameter at the suction opening should be off-center conversion, and should not be over the top. Increasing the diameter at the top will cause the air to shrink to the point where the first air blow into the pump will occur and cavitacin will occur.

What range of viscosity or viscosity is suitable for a centrifuge pump?

A: Centrifugal pumps or centrifugal pumps with similar properties are well pumped and for higher viscosity fluids, the American Standard Hydraulic Institute has set criteria, curves and tables that can be used to measure flow rates and flow rates. The pumpable head in the more viscous fluid estimated. But in general, it is not possible to provide a precise number for the viscosity of centrifugal pumps.

Which industries are vacuum pumps used for?

A: In addition to the food industry where vacuum pumps are widely used, they are also used to separate water from mines. In Iran, United Vacuum Pump is one of the manufacturers of vacuum pump. Also in the polyethylene industry, vacuum pumps are used to lift the pipe when the extruder comes out, so that the tubes do not stick together. Vacuum pumps are generally used wherever vacuum is required, and it should be noted that the use of these pumps can never achieve an absolute vacuum.

What is the magnitude of the static pressure increase on the centrifugal screw pump housing?

Answer: On average, static pressure in the shell is about one-third the static pressure in the pump impeller.

In a centrifuge or centrifugal electropump, what are the energy changes?

A: First, in an electric motor, mechanical energy is converted into kinetic energy in a mechanical impeller, and in a kinetic energy shell, it is compressed.

What is a Coupling? How to mount the motor and the coupling pump?

Answer: Correct coupling between the motor and the pump is one of the most important parts of mounting an electropump. Generally the motor and pump are coupled to the coupling. Normally, multi-threaded couplings are used which have tires used as bumpers. It is important to place the clutch part on the motor and the horn on the pump. The reason is that since the electromotor may be set up for testing, if the horned part is attached to it, the risk of the tentacles being involved with people's clothing is high and may be dangerous. The couplings are seamless and will be selected according to the shaft dimensions and torque that must be transmitted.

What is an Electropump Chassis?

A: Chassis is generally used to meet the requirements set by the pump manufacturer for installation where the electromotor and pump are to be used. For example, Pumpiran Company has charts that indicate the type of chassis for each pump. It should be noted that the values shown in these charts are based on standard engineering charts and that the specifications of the chassis used are consistent with the standard charts. Chassis will generally be mounted on a concrete foundation by bolts.

Our previous electropump was powered by a 3,000 7.5 kW motor and was damaged. We now have a 15 kW engine in the 3000 mpg. Are we allowed to replace these two together?

A: Generally, any motor that has more than the absorption power of the pump can be operated. In other words, the pump will be powered by the same 7.5 kW engine. The point is that the efficiency of the higher power motor, so-called idle running, will be lower.

In the deep-suction pump, do you need a one-way valve at the end of the pipe?

Answer: One-way valves or valves are one of the most important tools needed at the bottom of the pump-connected suction pipe. This valve must be fully sealed so that there is some water between the bottom tank and the pump. Also the installed pump must be capable of being watered.

What should be the maximum soluble air percentage?

A: Generally the permissible soluble air content for centrifugal or centrifugal pumps is less than 6%. As the amount of water soluble gas increases, the pump head and discharge will decrease and the pump characteristic curve will tend to zero.

Is the centrifugal pump or centrifuge suction itself?

Answer: By the complicated hydraulic and mathematical equations, it can be shown that these pumps are still not suctioning themselves, even though they run thousands of yards.

In the centrifuge or centrifugal electropump, does it require ventilation after the pump is installed and before commissioning?

A: After installing the electropump at the desired location, it should be primed for startup. In such a way as to fully pump the pump and then start. It should be noted that in small pumps with impeller rotation, we also release air inside the impellers. It is noted that in a flooded pump, we do not start the pump in any way before priming it, as there is a possibility of burning jaws or jaws.

What can be done to prevent a deep well wall from falling?

A: One of the most important reasons for dropping a well is the high vibration of the floating electropump in the well. Using tools such as an inverter or drive to start and shut off the electropump will greatly reduce the vibration of the floating electropump.

What is a round foam pump?

A: In floating pumps forI Overcome NIFaceI AxisI Pumps use floor matsIBe. After the bootI Floating pump fILemI Out of the waterIRound toe floorIAnd prevent frictionIRIwill do. Round floor pieces are generally fromIL and graphIMade by M.I Be.

Why pump butterfly nutIOpen from centerIBe?

Answer: DellIMajor forI Opening of the cross pump impellerIF.IVaje is generally aIThis is due to the return of water from the drift openings into the pump which may be due to the padITen ram rounds occur, the impeller in the opposite direction of the wheelI10 And since the shaft is fixed, the propeller nut will open.